2023. 2. 24. 23:45ㆍEngineering

Abstract. The importance of epidermal device has been increasingly raised since it is found to be used in human-machine interfaces and intimate interactions between human body and the measurement device. However, rough and rigid textile of the structure was the main obstacle which decreases the conformal contact, lowering the performance of the device. Therefore, flexible micro-structure has been developed to overcome the issue. In this research, serpentine structure is used to design the strechable sensor. Also, the sensor is placed on a human-fiendly substrate and measures the musle motion by recieving the EMG signal.

Introduction/Background

A. Epidermal Electronics

Epidermal electronic system(EES) is a class of integrated electronic systems that are ultrathin, soft, and lightweight, such that it could be mounted to the epidermis based on van der Waals interactions alone, yet provides robust, intimate contact to the skin. The technology enables many medical applications to monitor body activities, or to realize human-machine interface.

B. Serpentine structure

Serpentine structure is a symmetric structure of S-shaped curves used in epidermal electronics. By its wavey curve, it is able to implement strechable silicon integrated circuits to be attached to, for example, skin.

C. Photolithography

- Photolithography is a printing method used in a micro-fabrication to pattern on a substrate using UV light. The process of photolithography contains deposition of photoresist.

- Photoresist(PR) is a material that is light-sensitive which can be used to form a patterned coating on a surface. Positive PR becomes soluble under the exposure of light, while negative PR becomes insoluble under same condition.

D. Photomask

Photomask has physical demansions containing patterns. Chrome mask is a computerized direct writing using E-beam while emulsion mask uses photoreduction from the master film.

E. Etching

Etching is a process that removes materials selectively by an etchant, to precisely transfer the pattern of the mask onto the wafer surface.

F. Electromyography(EMG)

Electromyography is a technique of recording the electrical activity using electrodes applied on the surface(skin) or by implanting into the muscle to sense the signals. EMG signals have very small amplitude so it needs an amplifier in addition to the sensors. Also, filters are required to gain clean power spectrum.

G. Transfer Printing

Transfer printing is a technology that assembles small materials into spatially organized functional array. Large-scale components can be divided into smaller substrates, and result of conventional process can be moved to flexible and strechable substrates.

Design

Mask design for an EMG sensor contains 3 electrodes. To acheive the goal that device must be streched about ~30%, serpentine structure is applied. AutoCAD is used to design the layout.

Specifically, serpentine unit is a shape of a weather vane which angle is shown above. Whole units are eventually gathered in circle shape.

Fabrication Process

a. Degreasing the substrate / Making PDMS solution

- Before the fabrication, degrease the glass slide with Acetone, IPA, and DI water. Then, it shoud be well-dried by Nitrogen gas.

- Mix the SYLGARD 184 Silicone Elastomer Kit in the ration of 10 : 1 (big : small) and then remove the bubbles using the descicator and vaccum pump for 45 minutes. Spin coat the PDMS solution on a glass slide at 3000rpm, 5sec(ramp), 30sec(dwell). Lastly, preheat the sample at 120℃ hot plate for 20 minutes.

- Each steps are held one after another with minimum delay in between. First, put the sample in the UV box for 5 minutes. Then, spin coat polyimide(PI) on a sample in two steps(500rpm, 5sec, 5.5sec / 4000rpm, 5sec, 60sec). After coating is finished, breifly place the sample on 150℃ plate for 5 minutes. Lastly, bake at 250℃ for 70 minutes in the vacuum oven.

b. Metal deposition

Deposit Cr(10nm) and Au(150nm) on a baked PDMS sample using E-beam evaporator.

c. Metal patterning

- Again, degrease the manufactured substrate with Acetone, IPA, and DI water. Then, it is well-dried by Nitrogen gas.

- Spin coat with AZ GXR-601(positive PR) in two steps (2000rpm, 5sec, 2sec / 4000rpm, 5sec, 30sec). Then, softly bake at 90℃ in the vacuum oven.

- Following the mask design, align the mask using mask/wafer aligner(MJB4) and expose UV light(22mJ). Then, post exposure bake on 110℃ for 3 minutes in the vacuum oven.

- Put the sample in positive PR developer(AZ 3000 MIF) and stir it for 35 seconds. Then wash with DI water and dry it with Nitrogen gas. Finally, check if the sample is well developed with the microscope.

- Put the sample into the Gold etchant and stir it for 30 seconds. Wash with DI water and dry it using Nitrogen gas. Check the sample by observing with the microscope. If it is well-etched, do the same process with Chrome etchant. This time, stir if for 5 seconds. Lastly, remove PR using acetone, IPA, DI water and dry it using Nitrogen gas.

d. PI Deposition and RIE

- Spin coat PI on the sample in two steps (500rpm, 5sec, 5.5sec / 4000rpm, 5sec, 60sec). Then, place the sample on 150℃ plate for 5 minutes.

- Bake in 250℃ vacuum oven for 70 minutes. Then spin coat with AZ 10XT(positive PR) at 3000rpm, 5sec, 30sec and again soft bake on 110℃ oven for 5 minutes.

- Align PI mask precisely using MJB4 and expose UV(360mJ).

- Put it in AZ 300 MIF for 10 minutes and wash it with DI water. Then, dry it with Nitrogen gas.

- Etch PI layer with ICP asher and under condition of O2 50sccm, power 200W, time 60 min.

- Remove PR with Accetone, IPA, DI water and dry it using Nitrogen gas.

e. Transfer printing

- First, place the device on a 120℃ hot plate. Then, attach the medical tape on a clean glass slide to use as a substrate.

- Fix the glass substrate on a table using a double-sided tape, and attach the heated device on it. Then, move the fabricated device to a water soluble tape. After attaching the tape, applying a strong force at a moment would be helpful. Check if only PDMS layer still remains on the glass, and PI layers and gold layer is well transferred.

- Glue the water soluble tape onto the medical tape. Then, drop water on the tape and remove it after few minutes. Lastly, rinse with DI water for sure.

Characterization and/or Experiments

a. Prepare measurment

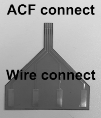

- Prepare a flexible PCB. It is designed to match the wire of ACF cable. Large contact pades are for wire soldering.

- Apply soldering paste to the contact pad and heat the stripped part of wires. Repeat three times in order to connect three electrodes.

- Cut the ACF cable containing three wires and connect to the PCB by applying heat and pressure using hair iron.

- Connect the fabricated sensor and ACF cable by applying heat and pressure.

- Attach the medical tape(with the sensor) to the skin.

- Connect a measurement device including instrumentation amplifier and filters.

- Repeat relaxation and contraction of the muscle and capture the EMG signal.

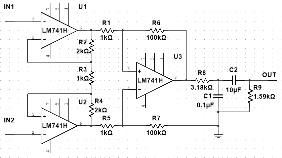

b. Measurement circuit

- Gain : 500

- Cutoff frequency : 10Hz, 500Hz

- Used components : op-amps, resistors, capacitors

- Three electrodes are attached to the skin, each is used to recieve the signal for measurement, base, and ground.

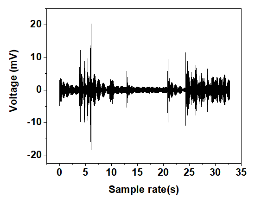

c. Measurement result

The experiment was held by attaching the sensor on the experimentor's left arm. The sampling rate is setted as 1/2000 second, and the volage unit is mV.

Discussion

The observed result shows that epidermal device is able to sense the muscle motion by motor unit(MU), which is an electrical activity. The graph clearly shows the difference in range of voltage change(from 0~10 and 20~30), which proves that the electrical signal was sent by the motor nerves to muscle fibers create force during the muscle contraction.

Conclusions

The result of the research is that epidermal device sucessfully detects EMG signal of the human body and represents into voltage graph clearly. Main acheivement is that the sensor of the device is designed in serpentine structure which dramatically increases the conformal contact at the interface. Also, the device is applied on the medical tape, which is human-friendly substrate.

References

[1] S. Wang et al., “Mechanics of Epidermal Electronics.”,J. Appl. Mech., vol. 79, no.3, Apr. 2012, doi: 10.1115/1.4005963.

[2] T. Widlund, S. Yang, Y. Y. Hsu, and N. Lu, “Stretchability and compliance of freestanding serpentine-shaped ribbons,” Int. J. Solids Struct., vol. 51, no. 23–24, pp. 4026–4037, Nov. 2014, doi: 10.1016/J.IJSOLSTR.2014.

07.025.

[3] M. B. I. Reaz, M. S. Hussain, and F. Mohd-Yasin, “Techniques of EMG signal analysis: detection, processing, classification and applications,” Biol. Proced. Online, vol. 8, no. 1, p. 11, Mar. 2006, doi: 10.1251/BPO115.

[4] C. Linghu, S. Zhang, C. Wang, and J. Song, “Transfer printing techniques for flexible and stretchable inorganic electronics,” npj Flex. Electron. 2018 21, vol. 2, no. 1, pp. 1–14, Oct. 2018, doi: 10.1038/s41528-018-0037-x.

'Engineering' 카테고리의 다른 글

| Graphene Contact Resistance 최근 동향 (0) | 2023.02.25 |

|---|---|

| Van der Waals Contact을 이용한 차세대 반도체 (0) | 2023.02.25 |

| TCAD를 사용한 P-N Junction Simulation (0) | 2023.02.24 |

| 고등학교 졸업 논문 (0) | 2023.02.24 |

| 아이디어 구상 : 급형 공중 풍력발전 (0) | 2023.02.24 |